latest News

Not only are the lasers under power, but things are also heating up in our company.

Here’s what’s been happening in our company lately:

Laser Cladding

Laser cladding has long been an integral part of industries such as automotive. Special focus on brake disks!

Battery welding

Short and fast welding processes require solid process monitoring to detect even the smallest deviations.

Kunststoffschweißen

While process monitoring with metal relies on light emissions, sound monitoring is suitable for other materials.

Monitoring joining processes

Today, virtually every industry cannot operate and deliver without high-quality, successful joining.

Not only in the aerospace and automotive industries, but also in the production of luxury goods or medical technology, process monitoring is an important issue that requires the highest precision.

However, many companies still do not have sufficient process monitoring mechanisms in place to accurately and reliably verify the required quality at all times.

Faulty assembly processes not only result in horrendous scrap rates. Defective components lead to downtime and delivery delays. Defects can also lead to product recalls, which can cause significant financial damage.

the weldmetrix

method

Just as the laser is focused on the workpiece, our focus is on process monitoring of industrial joining processes.

Joining processes are monitored and improved with our sensor and our PROMOS software platform, regardless of the industry. Companies use the 1 MHz WLDR sensor and our software.

The WLDR sensor is installed using adapters either directly in the laser source, on the camera adapter of the welding optics, or using external mounts.

The software can not only be operated from the PC, but can also be accessed via laptop, tablet and even smartphone, so that it can be viewed by those responsible regardless of time and place.

Whether it is a new installation for you or whether an existing system is to be supplemented, neither is a problem for weldmetrix!

External sensors can also be seamlessly integrated into the PROMOS Suite.

If no process monitoring system existed before, or if a change is desired, companies also have the option of setting up their entire production monitoring via our systems.

Companies

who care about their processes

Joining processes

in different industries

Joining processes are used in the manufacture of a wide range of products, regardless of the industry. Our focus is to ensure that each weld or joint is completed to the highest quality and without defects, regardless of the industry.

Each industry has unique requirements that can be met by customizing the weldmetrix WLDR sensor and PROMOS process monitoring suite.

In these and other industries, photodiode-based process monitoring systems that analyze light emitted and reflected radiation are helpful and useful.

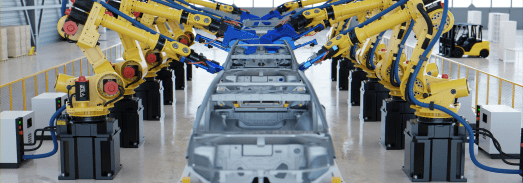

Automotive

In the automotive industry, joining processes are critical to the production of body, transmission and engine components. Strength, safety and efficiency are the top priorities for welding processes.

The importance of process optimization in the automotive industry is particularly evident in cases where things have not gone smoothly:

- Fuel leakage due to defective welds on the fuel tank

- Unpredictable airbag deployment while driving

- Failure of seat belt pretensioners to deploy

Aerospace & Aviation

Workpieces in the aerospace industry are subjected to even greater stresses than those in the automotive industry. Not only the requirements, but also special processes such as friction stir welding present companies with new challenges in process optimization.

Another important process in aerospace is additive manufacturing, which, like other joining processes, requires the most precise monitoring.

Powder Bed Fusion (PBM) is used in the manufacture of cabin and engine components to make them stronger and lighter.

Electric Mobility

Electromobility not only represents our future in terms of mobility, but also shows us which production processes we will have to deal with more closely in the future.

Electromobility is also closely related to battery welding processes.

Medical Technology

In no other industry are human lives as directly at stake as in medical technology. From pacemakers to lab equipment, where lives hang in the balance, nothing can be left to chance in manufacturing.

From laser to additive manufacturing, every process must be right.

Green Energy

High welding speeds and difficult to control processes place high demands on manufacturers.

In order to guarantee the functionality of the batteries after the welding process, the highest level of precision is required. In many areas of green energy, batteries are an irreplaceable component – where batteries are processed, the highest joining speeds and precision are required, leaving no room for error.

Complete and accurate process monitoring is essential.

Luxury goods

Wherever luxury goods are manufactured and processed, high-quality materials are used. Not only must these materials be handled with the utmost care, but the luxury goods industry must also avoid material waste.

Household appliances / White goods

We use them every day and are grateful for the daily conveniences they provide.

Likewise, we expect our appliances to work day in and day out-for a long time.

For manufacturers, it’s a challenge to balance efficiency and quality.

Process monitoring

is crucial

to continuously improve the efficiency, quality, and competitiveness of an organization. By systematically analyzing and adapting workflows, you can better utilize resources, reduce costs, and increase customer satisfaction.

weldmetrix GmbH

elevating standards, monitoring success

Headquarter

Gutheil Schoder Gasse 17

Techpark Vienna

1230 Vienna

Austria

Copyright © 2023 – weldmetrix GmbH