SOLUTIONS

WLDR Sensor & PROMOS Suite

by weldmetrix

Developed in-house and tailored to individual needs, the WLDR sensor and the PROMOS process monitoring suite work together.

Die Software wird beliebig für diverse Usecases erweitert. Der WLDR-Sensor funktioniert in der PROMOS Suite, wir könne in unsere xx Auch die Software kann herstellerunabhängig andere Sensoren auslesen und in das Software-System integrieren.

The Comperative System

how weldmetrix works

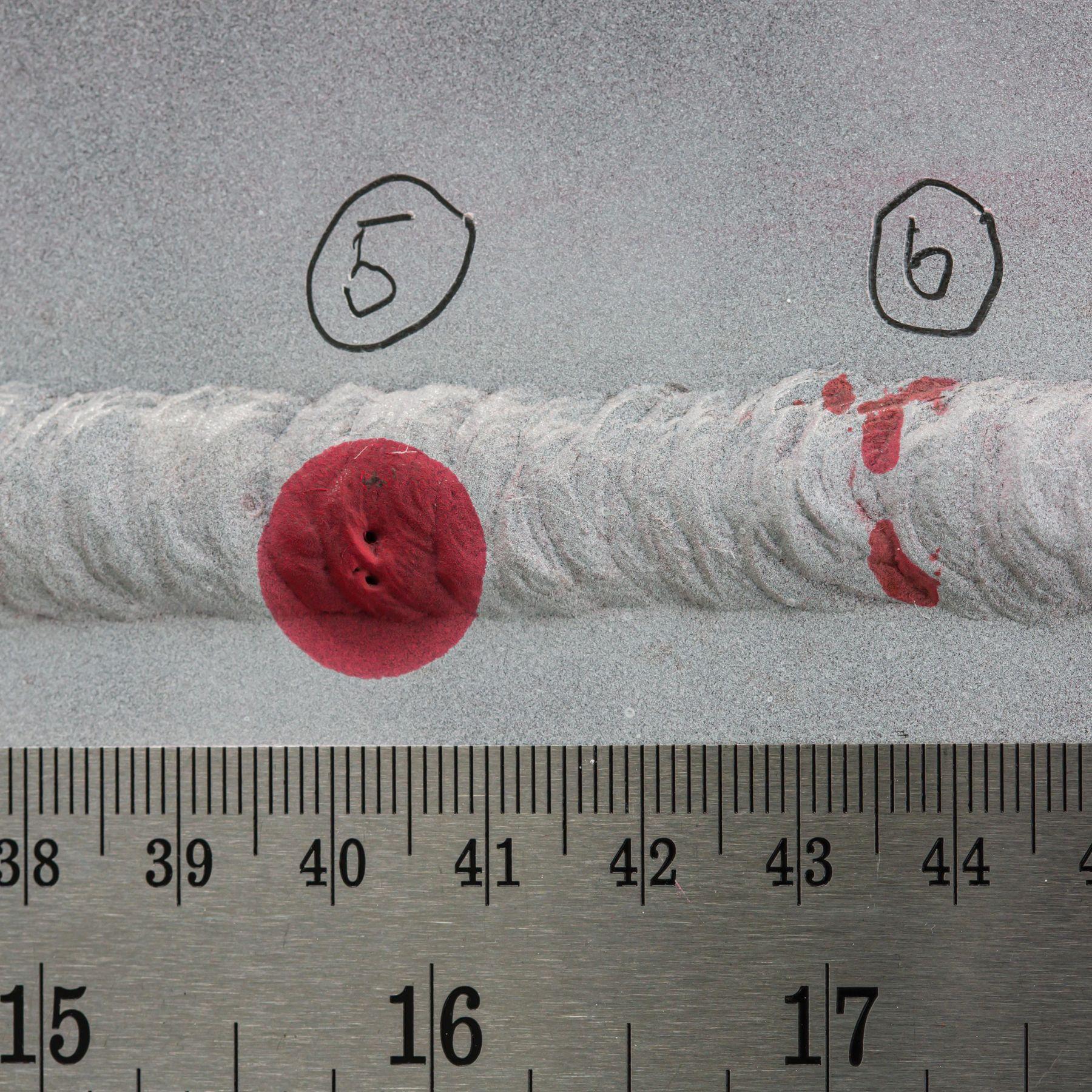

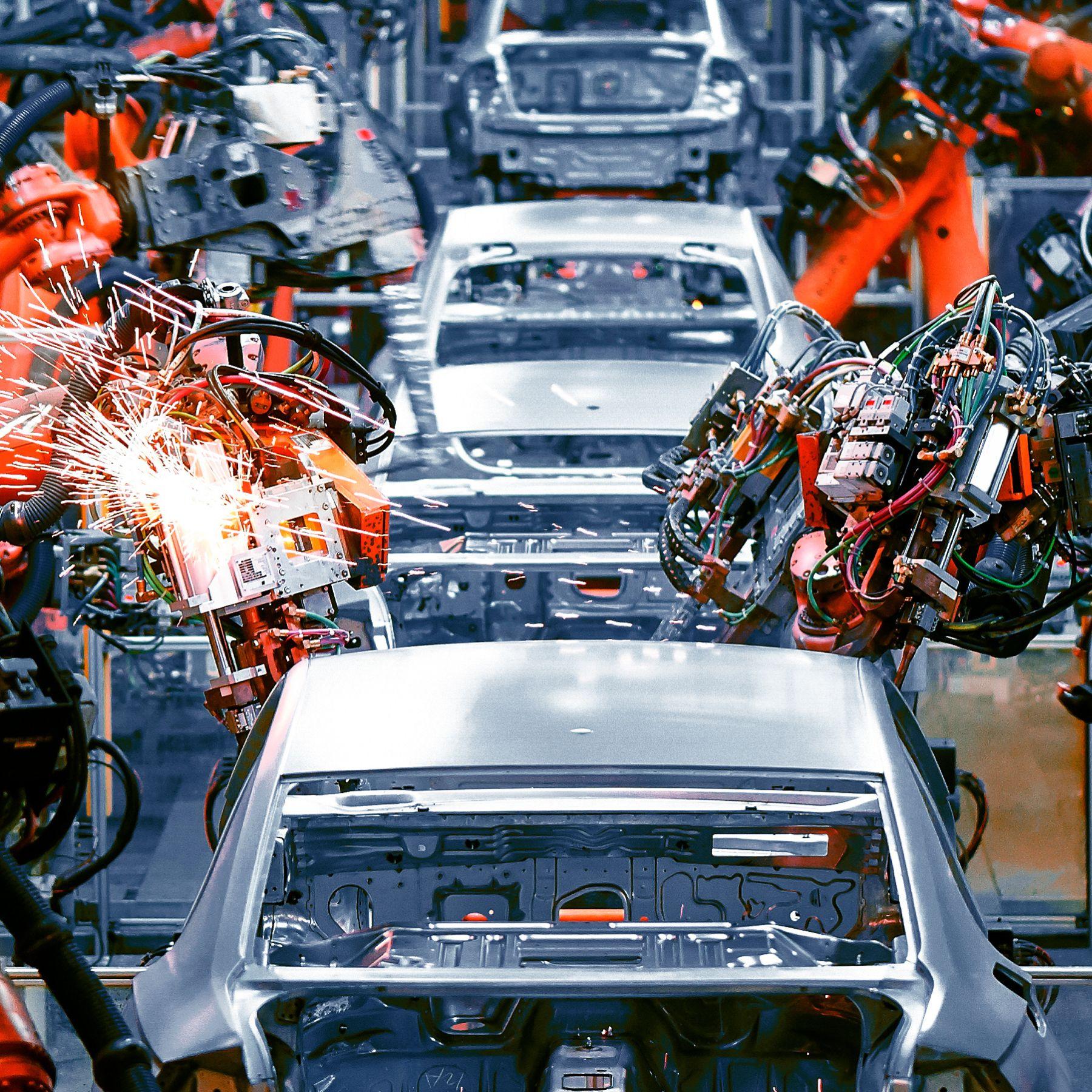

The Weldmetrix technology is based on a comparative system. A comparative system in process monitoring for joining processes works by comparing data from a running process with reference data collected under ideal conditions. During the process, the system continuously measures and monitors certain parameters by measuring light emissions.

If the measured values deviate significantly from the reference values, the system identifies them as potential faults and triggers a warning or even a production stop at the customer’s request.

read more

Comparative systems have the advantage of being relatively easy to implement and operate and are capable of continuous monitoring throughout the process. They are particularly well suited to processes where parameters must be closely monitored to ensure consistent quality. Their main disadvantage is that they work on the basis of comparative data and therefore only identify deviations and do not agree on the exact cause of the defect.

Measurement systems have the advantage of allowing direct assessment of the source of the defect. However, they can be more complex to implement and operate, often requiring specialized equipment and knowledge. They can also be more time consuming and are not suitable for all production environments.

Advantages of the comparative system in process monitoring

Detect even the smallest deviations

Evaluation is performed directly during production

No need to destroy the part to check quality

Early detection of process drift

WLDR Sensor

The Weldmetrix WLDR sensor represents a significant innovation in sensor technology. As a highly sensitive sensor, it reliably detects the emitted and reflected radiation of a joining process with a workpiece.

Depending on the sensor type, it covers a wavelength range of 320 – 1100nm or 800 – 1700nm, enabling precise and comprehensive analysis of the joining process.

Its small size of only 42mm x 42mm x 22mm allows easy integration into a variety of production environments, while the high sampling rate of up to 1 MHz ensures efficient and timely process monitoring.

This makes the WLDR sensor an effective tool for monitoring welding processes without disrupting operations or production efficiency.

Another key advantage of the WLDR sensor is its flexibility in integration.

It can be integrated directly into the laser source, via the camera adapter of a (laser) welding optics, externally directly on the process or via an optical fiber. These various integration options allow the sensor to be optimally adapted to the specific needs and requirements of the respective production environment.

up to MhZ sampling rate

mm large

nm Wavelength range

nm Wavelength range

PROMOS Suite

With the Process Monitoring Suite, weldmetrix offers a highly modular software platform that can be flexibly adapted to the specific requirements of each individual customer.

Combined with our specially developed WLDR sensor, it allows you to monitor and control a wide range of light-emitting production processes. In addition, other data sources can be integrated, making our system a versatile tool for monitoring your production processes.

The processing and evaluation of data in the Process Monitoring Suite can be freely defined according to your specific needs. This allows you to create a customized solution that fits your processes and helps you achieve your quality goals.

As an independent vendor with flat hierarchies and extensive in-house expertise, we are able to respond quickly and flexibly to your needs. Our expertise enables us to integrate existing third-party sensors into our software, providing you with a complete, efficient solution from a single source.

At weldmetrix, we believe in providing our customers not only with technologically advanced products, but also with a service that is tailored to their individual needs. Therefore, we always strive to provide you with the highest possible quality and efficiency in process monitoring. The benefit to your core competencies is always at the center of our considerations.